Call: 08045476698

Pit Mounted Scissor Lift

MOQ : 1 Piece

Pit Mounted Scissor Lift Specification

- Voltage

- 220-240 Volt (v)

- Type

- Scissor Lift

- Usage

- Freight Elevator, cargo Lift

- Material

- Steel

- Drive Type

- AC

- Mechanism Type

- Scissor Lift

- Safety Device

- Safety Sensor

Pit Mounted Scissor Lift Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Month

- Delivery Time

- 2-60 Days

About Pit Mounted Scissor Lift

Pit Mounted Scissor Lift provides a simple solution for loading and unloading cargo. With a push of a button the difference between loading bay and the truck is over come enabling smooth movement of cargo. Pit Mounted Scissor Lift is suitable for loading and unloading from vans, canters trucks & containers.

Engineered for Heavy-Duty Performance

The Pit Mounted Scissor Lift stands out with its durable steel construction and robust scissor mechanism. Designed to handle a wide range of industrial and commercial lifting needs, it guarantees reliable operation for intensive freight or cargo handling tasks.

Reliable Safety Features

Equipped with advanced safety sensors, this lift safeguards both personnel and materials during operation. These features ensure compliance with stringent safety regulations and provide users with peace of mind during demanding work cycles.

FAQs of Pit Mounted Scissor Lift:

Q: How does a pit mounted scissor lift operate?

A: The pit mounted scissor lift functions by using a scissor mechanism powered by an AC drive operating at 220-240 volts. When activated, hydraulic or electromechanical systems move the steel arms, smoothly raising or lowering the platform as required.Q: What applications are ideal for this scissor lift?

A: This lift is primarily used as a freight elevator or cargo lift in warehouses, logistics hubs, and industrial facilities. Its sturdy build and efficient mechanism make it suitable for moving heavy goods between floors with minimal effort.Q: When should a pit mounted installation be considered?

A: A pit mounted lift is recommended when you need the lift platform to be flush with the ground level for easy loading and unloading. Installations in new builds or renovations often employ pit mounting to enable seamless material handling.Q: Where can I have this scissor lift installed?

A: This type of lift is commonly installed at material handling bays, loading docks, factory floors, and large storage facilities where moving goods between levels is a frequent requirement.Q: What process is followed for installation and commissioning?

A: The installation involves preparing a pit of suitable dimensions, securing the lift structure within it, and connecting the electrical components. Once structural and safety checks are complete, the manufacturer or supplier will test and commission the lift for use.Q: How does the integrated safety sensor benefit users?

A: The safety sensor continually monitors lift operation, automatically halting movement if an obstruction or unsafe condition is detected. This greatly reduces the risk of accidents, safeguarding both personnel and valuable cargo during every lift cycle.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Scissor Lift Category

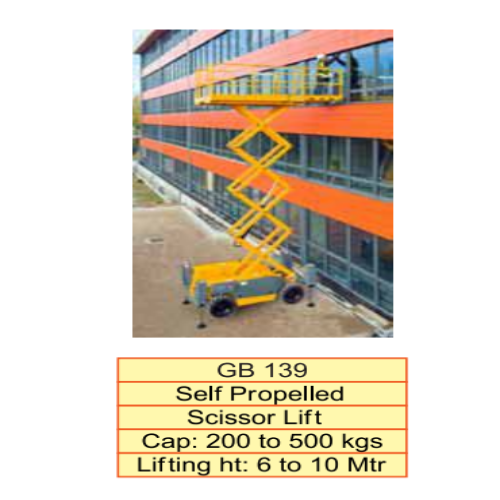

Self Propelled Scissor Lift

Price Range 10000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Max. Lifting Height : 610 Meter (m)

Color : Yellow & Silver

Min. Lifting Height : 6 Meter (m)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry